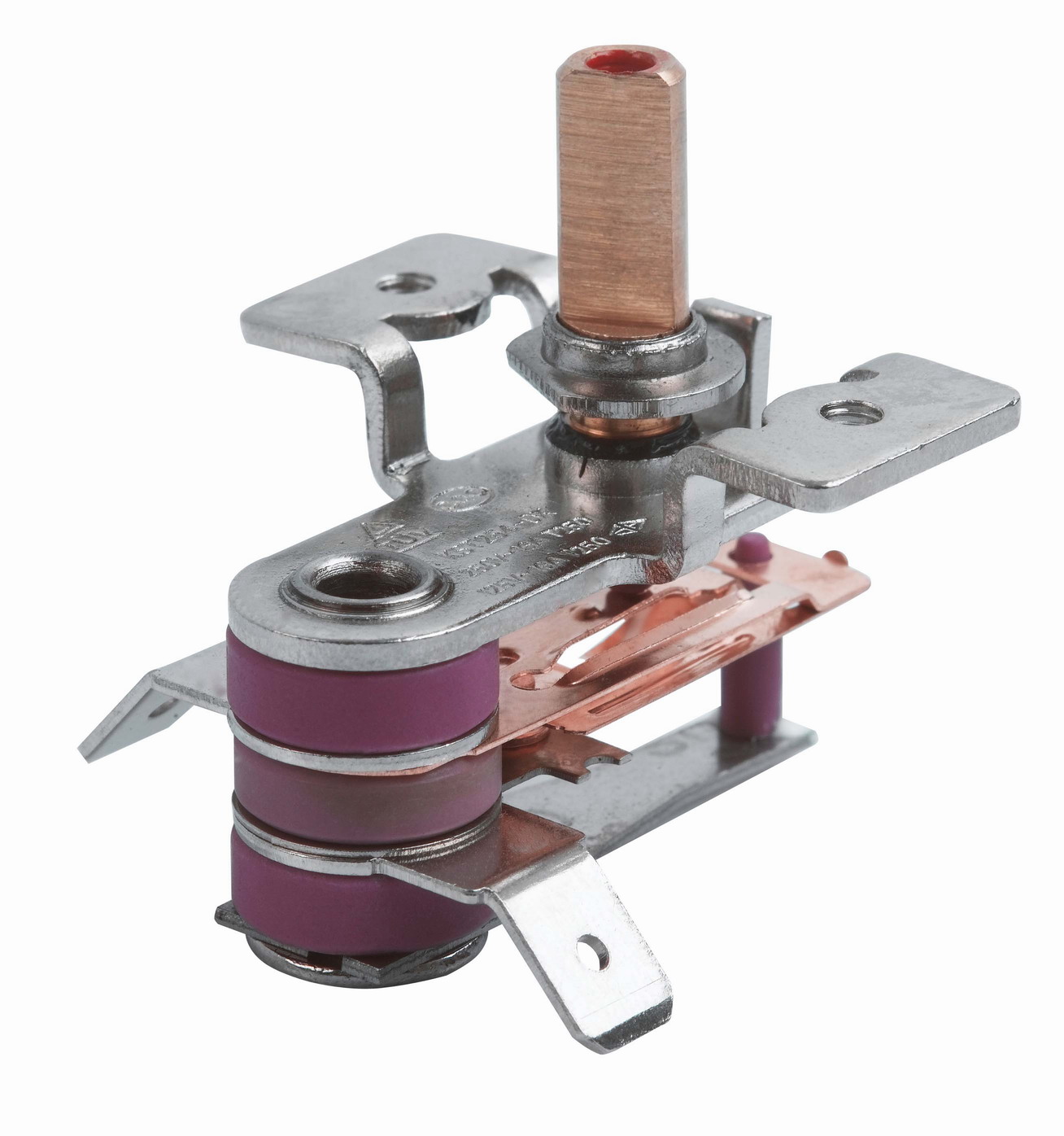

A bimetal thermostat is a type of temperature-sensitive switch that operates based on the differential thermal expansion of two dissimilar metals bonded together. Here's a description of a bimetal thermostat:

Composition: A bimetal thermostat is made from two thin layers of metal, such as brass and steel, which are bonded together. These metals have different coefficients of thermal expansion.

Operation: When the bimetallic strip is heated, the layer that expands more (usually the brass) will cause the strip to bend. The degree of bending is proportional to the temperature change.

Switching Action: The bimetal strip is connected to a mechanical linkage that operates a switch. As the strip bends with the increase in temperature, it can open or close the switch, thereby controlling the flow of electricity to a device, such as a heating element.

Applications: Bimetal thermostats are commonly used in applications requiring precise temperature control, such as in electric irons, toasters, and other appliances where overheating could be a concern.

Advantages: They offer a simple, reliable, and cost-effective method of temperature control. They are also robust and can withstand a wide range of temperatures.

Limitations: The response time of a bimetal thermostat can be relatively slow due to the time it takes for the metal to heat up and cool down. Additionally, they are typically used for on/off control rather than precise temperature regulation.

Safety Features: In many devices, bimetal thermostats are used as a safety feature to prevent overheating and potential hazards.

Calibration: The sensitivity of a bimetal thermostat can be adjusted by altering the thickness, composition, or shape of the bimetallic strip, allowing for customization to specific applications.

The bimetal thermostat is a fundamental component in many temperature control systems, providing a mechanical solution to electrically manage temperature-sensitive operations.