Nothing ruins a carefully prepared meal faster than an appliance that refuses to cooperate. You spend hours prepping ingredients, only to find burnt edges, raw centers, or an oven that simply refuses to heat up. This unpredictability creates significant frustration in the kitchen. It turns cooking from a joy into a guessing game where your expensive ingredients are the primary casualties.

However, these temperature issues represent more than just culinary inconveniences. A malfunctioning unit can pose legitimate safety risks, particularly in gas models where erratic heating might indicate combustion control issues. Furthermore, ignoring these signs often leads to higher energy bills as the appliance struggles to maintain regulation.

This guide moves beyond guessing. We will define how to differentiate between simple calibration drifts and catastrophic hardware failure. By understanding the root cause, you can confidently decide whether to calibrate your existing settings, perform a specific repair, or replace the unit entirely. You will learn the specific diagnostic steps professional technicians use to isolate the problem.

Key Takeaways

Symptom vs. Reality: Not all temperature variances indicate a broken part; understanding thermal swing is critical before buying spares.

The Two Types: Testing methods differ drastically between mechanical capillary thermostats (continuity test) and modern electronic sensors (resistance test).

The Igniter Trap: In gas ovens, a weak igniter often mimics a bad thermostat.

Testing Standard: Do not use analog dial thermometers for diagnosis; a digital probe or multimeter is required for accurate decision-making.

1. Signs Your Oven Thermostat Is Failing (vs. Normal Operation)

Before you rush to purchase replacement parts, you must distinguish between normal thermodynamic physics and actual hardware faults. Many users replace a perfectly good oven thermostat because they misunderstand how ovens regulate heat. An oven does not maintain a perfectly flat temperature line. Instead, it operates on a cycle.

The Thermal Swing Reality

Ovens function by oscillating around a set point. When you set the dial to 180°C (350°F), the heating element or burner powers on until the cavity reaches perhaps 190°C. It then cuts power. The temperature slowly drifts down to roughly 170°C before the cycle repeats. This rise and fall is called thermal swing or amplitude.

Normal Operation: A variance of ±10–15°C (approximately 20–30°F) around your set point is standard for most residential appliances. This average heat cooks your food.

Faulty Operation: If you record variances exceeding 30°C, or if the temperature continues rising indefinitely without cutting off (runaway heating), the control mechanism has failed. This inability to regulate the cycle confirms the thermostat is no longer sensing or responding to the environment correctly.

Hardware Failure Symptoms

Beyond thermal swing, specific behaviors indicate the hardware has physically degraded. Watch for these distinct signs:

The All or Nothing Heat: This is the most common sign of a mechanical failure. The element or burner stays on 100% of the time, turning food into charcoal regardless of the dial setting. Conversely, it may never turn on at all because the switch contacts inside the thermostat have fused or broken.

The Drastic Offset: Your oven beeps to indicate it is preheated to 180°C, but an external digital probe reads only 120°C. While small offsets are calibration issues, massive discrepancies usually mean the sensor component has degraded.

Uneven Baking: If your cookies burn on the bottom but remain raw on top, the thermostat may be cycling too slowly. It allows the temperature to drop too low before re-engaging the element, preventing the consistent ambient heat required for even baking.

Physical Damage: Inspect the interior cavity. Visible pitting, corrosion, or kinks in the capillary tube or sensor probe suggest immediate failure. These components rely on gas expansion or resistance, both of which fail if the physical structure is compromised.

2. Pre-Purchase Diagnostics: Ruling Out Calibration and Airflow

Diagnosis involves elimination. Before ordering a new Electric Oven Thermostat or gas valve, apply this logic to rule out simpler, cheaper problems.

Step 1: The Calibration Check

Over time, mechanical springs weaken and electronic resistance drifts. This causes the center point of your temperature swing to shift.

Many modern ovens allow for a digital offset adjustment (typically ±15°C) via the settings menu. Older knobs often feature a calibration screw on the back of the dial itself.

Decision Point: If the temperature is consistently off by a fixed amount—for example, it is always exactly 20 degrees lower than the setting—this is a calibration issue. You can adjust this without parts. If the temperature is erratic and unpredictable, the hardware is failing.

Step 2: The Gas Oven Igniter Test (Crucial Distinction)

Gas ovens present a unique diagnostic challenge. A common scenario involves the oven failing to reach temperature or taking an hour to preheat.

In many gas units, the safety valve is wired in series with the igniter (glow bar). The gas valve will not open until the igniter pulls enough electrical current to heat up fully. As igniters age, they get weak. They might glow red, but they fail to draw enough amperage to open the gas valve.

Keyword Integration: A failing igniter increases resistance, mimicking a temperature-sensitive switch failure. If the glow bar turns red but the burner does not light, replace the igniter first. Do not replace the thermostat yet.

Step 3: The 30-Minute Cycle Test

Do not rely on instantaneous readings. To truly diagnose the unit, perform a cycle test.

Place a digital probe with a high-heat cable in the center of the middle rack.

Set the oven to 180°C (350°F).

Allow it to preheat.

Record the high peak and low valley temperatures over a 30-minute period.

Calculate the average of these numbers.

If the average matches your set point, the thermostat is working, even if the swing seems wide. If the average is wildly off, proceed to hardware testing.

3. The Technical Verification: How to Test with a Multimeter

Visual inspections and baking tests provide clues, but a multimeter provides proof. This section distinguishes between the two main technologies found in kitchens: mechanical thermostats and electronic sensors.

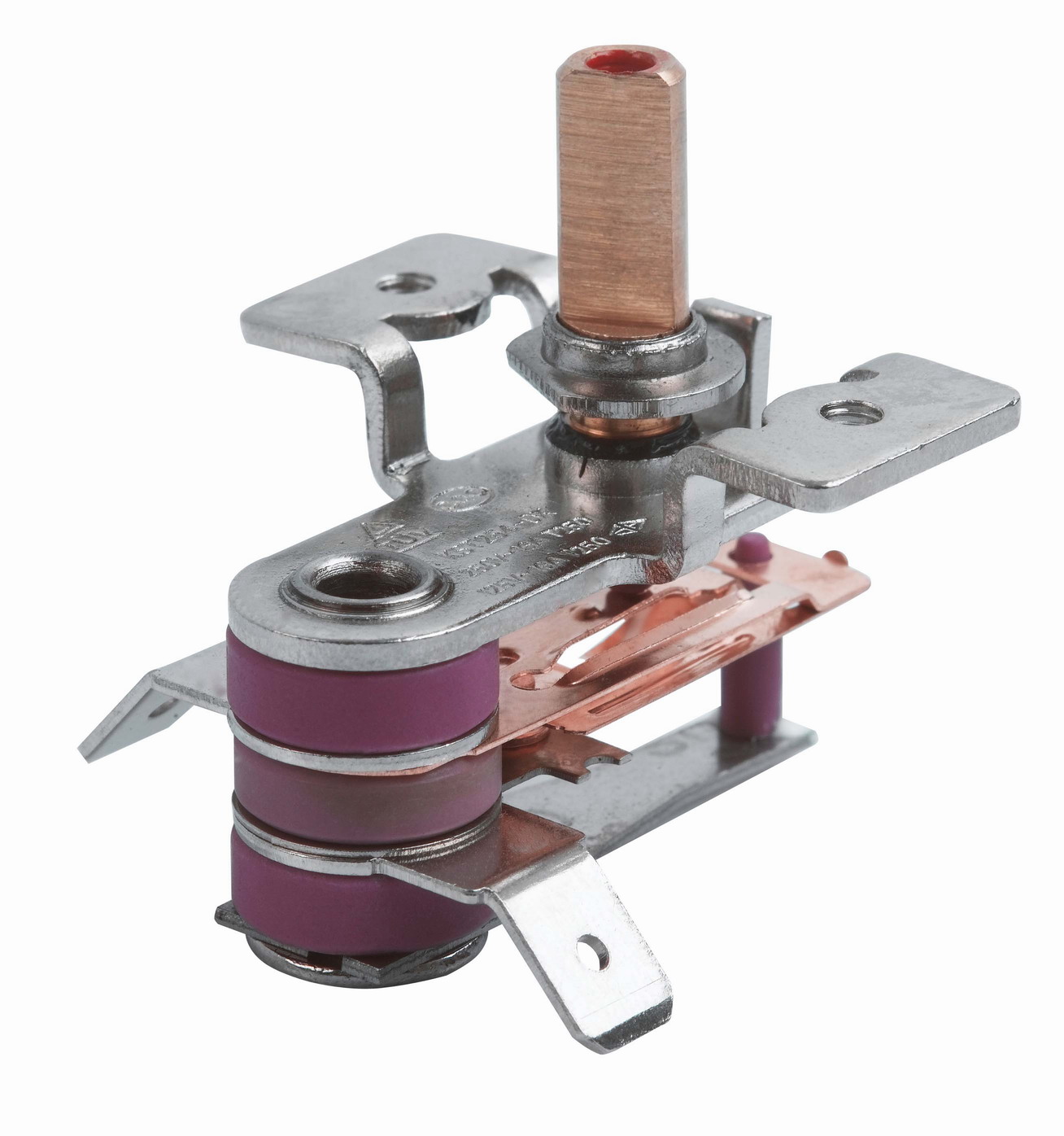

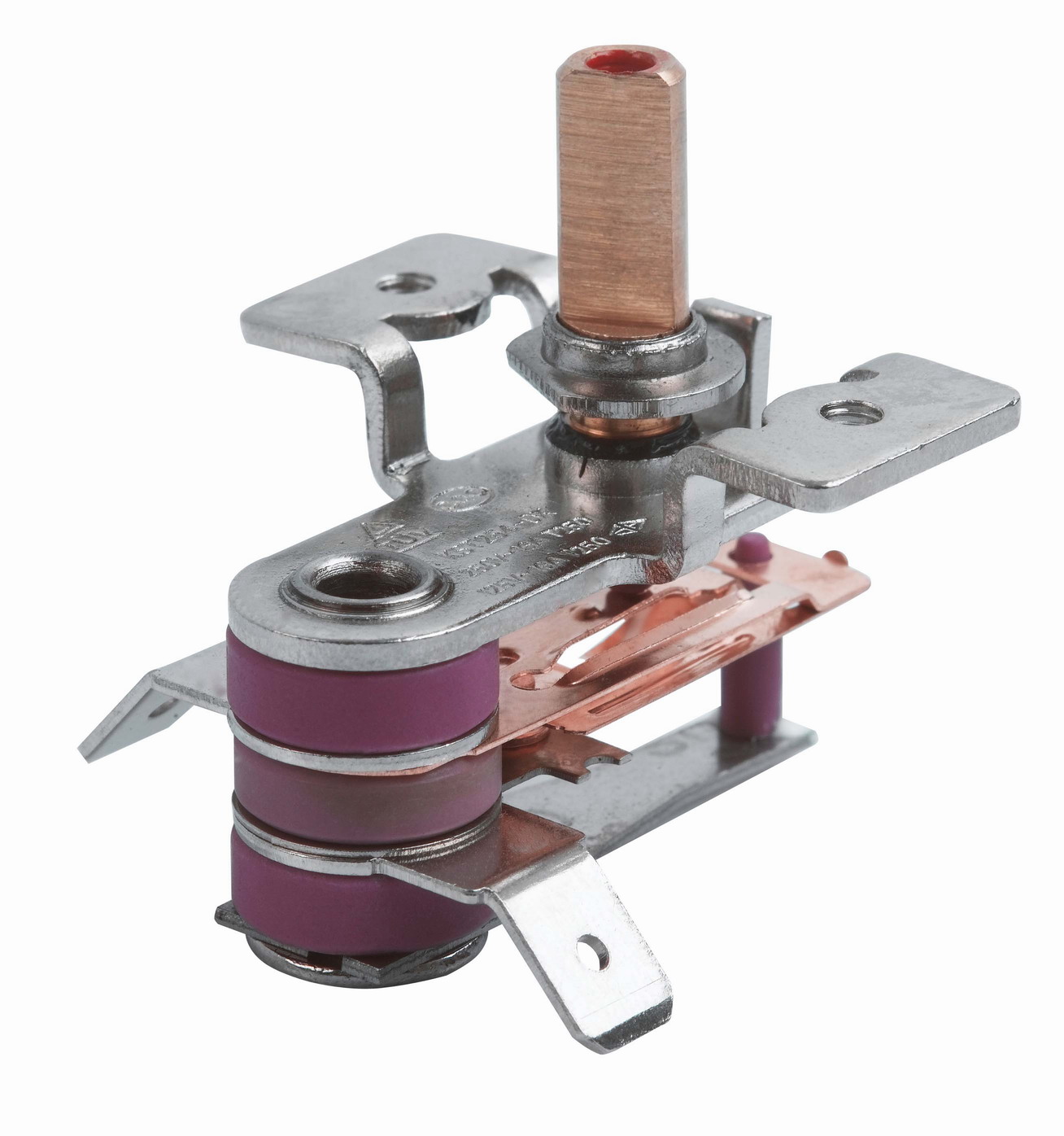

Scenario A: Mechanical / Capillary Thermostats (Older/Basic Ovens)

These devices are purely mechanical. They use a fluid-filled bulb connected to a long copper tube (capillary) and a bellows system. As the fluid heats, it expands, pushing the bellows to trigger a switch.

The Test (Continuity):

Power Off: Ensure total disconnection from mains electricity. Unplug the unit or flip the breaker.

Setting: Set your multimeter to Continuity (the beep symbol) or the lowest Ohms setting.

Room Temp: Connect the probes to the two terminals on the thermostat. It should show continuity (Closed Circuit / 0 Ohms). This means the switch is sending power to the element.

Heat Test: Apply gentle heat to the sensing bulb using a hair dryer. As it warms up, the fluid expands. Eventually, you should hear a click, and the multimeter should read Infinite Resistance (Open Loop).

Verdict: If the meter reads Open Loop (no continuity) while the bulb is at room temperature, the internal switch is broken. The part is dead.

Scenario B: Electronic Oven Temperature Sensors (Modern Ovens)

Modern appliances use an RTD (Resistance Temperature Detector) sensor. This is usually a pencil-thin metal rod sticking out of the back wall. It contains a resistor that changes its electrical value based on heat.

The Test (Resistance):

Setting: Set your multimeter to Ohms (use the 2k or 4k setting).

The Reference Standard: Access the sensor connector (usually requires removing the back panel). At room temperature (approx 21°C/70°F), a standard sensor should read between 1,000 and 1,100 Ohms.

Verdict:

A reading of 0 indicates a short circuit.

A reading of Infinite indicates an open loop (broken wire).

A reading significantly outside the 1000–1100 range (e.g., 2500 Ohms at room temp) implies the sensor has drifted.

In any of these three failure cases, the sensor requires immediate replacement.

4. Evaluation Criteria: Repair Costs vs. Replacement

Once you confirm the fault, you face a financial decision. Should you repair the existing appliance or invest in a new one? Use this breakdown to decide.

Cost Analysis (TCO)

| Expense Category | Estimated Cost | Notes |

| DIY Part (Sensor) | $20 – $50 | Simple electronic sensors are cheap and easy to swap. |

| DIY Part (Mechanical Valve) | $80 – $150 | Complex gas valves or older mechanical thermostats cost more. |

| Professional Repair | $250+ | Includes call-out fee, labor, and parts markup. |

A standard temperature-sensitive switch or electronic sensor usually represents a minor investment relative to the cost of the appliance. However, complex gas control valves can be expensive.

The 50% Rule

Industry experts recommend the 50% Rule. If the total cost of repair (parts plus labor) approaches 50% of the price of a brand-new comparable oven, replacement is generally the better long-term investment. New units come with warranties and better energy efficiency.

Age Considerations

Consider the lifespan of the unit. If the oven is over 10 years old and the thermostat is mechanical, other components are likely near failure. Door hinges, seals, and heating elements degrade over time. Replacing the thermostat on a 15-year-old oven often leads to a cascade of repairs where the next part fails months later. In this scenario, upgrading is safer.

5. Implementation Risks and Safety Compliance

If you decide to proceed with the repair, you must acknowledge the physical risks. Replacing oven components is not as benign as changing a lightbulb.

Gas Safety (Critical)

Replacing a thermostat in a gas oven often involves disturbing gas lines and valve connections. A small leak here can be catastrophic.

Compliance Note: In many jurisdictions, such as the UK and Australia, gas work requires a licensed professional by law. In the US, DIY is often permitted but requires strict leak testing. Always use a dedicated gas leak detector fluid or a soapy water solution to check every connection you touched. If bubbles form, you have a leak.

Electrical Safety

Ovens operate on high voltage (often 240V). The risk of shock is real. Always unplug the unit from the wall. Do not rely on just flipping the breaker, as mislabeled panels are common in residential homes. Furthermore, be aware of capacitors in control boards that can retain charge even after power is cut.

The Insulation Challenge

Accessing the thermostat typically requires removing the back panel. This exposes you to the fiberglass insulation that wraps the oven cavity. This material irritates the skin and lungs.

Recommendation: Wear gloves, long sleeves, and a mask to avoid skin and lung irritation. Work in a ventilated area if possible.

Capillary Tube Handling

For mechanical thermostats, the long copper capillary tube is the most fragile part of the system. It is hollow and carries the expansion fluid.

Warning: Kinking this hollow copper tube renders the new part instantly useless. If the tube kinks, the fluid cannot expand to the bellows, and the switch will never trigger. Handle it with extreme care during installation, unrolling it gently rather than pulling it tight.

Conclusion

A faulty oven does not have to mean an expensive replacement. By following a logical diagnostic path, you can save money and restore your kitchen's functionality. First, verify that the issue isn't simple calibration or a normal thermal swing. Second, isolate the component—checking the igniter on gas units and the sensor resistance on electric ones. Finally, validate your findings with a multimeter.

For modern ovens using electronic sensors ($20-$40), a DIY swap is almost always worth the return on investment. It is a quick repair that restores perfect accuracy. For complex gas valves or integrated control boards, weigh the age of the appliance against the high cost of the part. If you have identified the specific fault, use the search bar on our store to find the exact model number for your replacement.

FAQ

Q: How do I know if it's my heating element or my thermostat?

A: Perform a visual check first. If the element has blisters or breaks, it is the culprit. If the element looks fine, use a multimeter. A bad element reads Open Loop (broken circuit). If the element has continuity but never turns on (or never turns off), the thermostat is likely failing to send power correctly.

Q: Can I bypass the oven thermostat to test the oven?

A: No. Never do this. Bypassing the thermostat removes the safety control that stops the heating element. The oven will heat indefinitely, leading to a runaway thermal event that can melt wiring, destroy the appliance, and cause a severe house fire.

Q: Why is my oven temperature accurate at low heat but wrong at high heat?

A: This usually indicates resistance drift in electronic sensors. As the sensor ages, its internal resistance curve changes. It might be accurate at 100°C but provide wildly incorrect resistance data at 200°C, causing the control board to shut off heat prematurely or too late.

Q: Is an oven thermometer accurate enough for diagnosis?

A: An oven thermometer is excellent for identifying the symptom (e.g., "my oven is running cold"), but it cannot identify the root cause. It cannot tell you if the issue is the thermostat, the igniter, or the control board. You need a multimeter for that.