A dinner party can quickly go downhill when a roast is burnt on the outside but raw in the middle, or a batch of cookies refuses to bake properly. These inconsistencies are rarely a result of poor cooking skills. Instead, they often point to a failure in the appliance’s thermal regulation system. When an oven loses its ability to maintain a set temperature, it transforms from a reliable kitchen tool into a source of daily frustration.

Many homeowners assume this behavior signals the end of their appliance’s lifespan. However, replacing a thermostat is often a manageable DIY project. By handling this repair yourself, you can restore your oven's performance for a fraction of the cost of a new unit. While professional appliance repair can cost between $150 and $300, doing it yourself keeps money in your pocket.

This guide covers the replacement of mechanical thermostats and temperature sensors for electric ovens and ranges. We focus on safe, component-level replacement techniques. You will learn how to diagnose the issue, safely access the part, and utilize professional tricks to ensure a smooth installation.

Key Takeaways

Difficulty: Intermediate (Requires basic tool handling and removing panels).

Time Required: 45–90 minutes depending on oven style (Built-in vs. Range).

Cost Savings: Parts typically range $30–$100; professional labor saves $150+.

Crucial Tip: The String Trick is essential for routing capillary tubes through insulation without damage.

Diagnostic Phase: Is it Definitely the Oven Thermostat?

Before ordering parts or dismantling your kitchen, you must confirm the root cause. Many users confuse a broken heating element with a broken thermostat. Replacing the wrong part wastes time and money. You need to distinguish between a heat generation failure and a heat regulation failure.

Symptoms vs. Root Cause

A failed heating element presents differently than a failed thermostat. Use this comparison to identify your specific issue:

| Symptom | Likely Culprit | Visual/Operational Signs |

| Oven is completely cold | Heating Element | The element may have visible breaks, blisters, or burn marks. It never glows red. |

| Food burns quickly | Oven Thermostat | The temperature rises uncontrollably. The element stays on continuously without cycling. |

| Preheat light stays on | Oven Thermostat | The oven never registers that it has reached the target temperature. |

| Wild temperature swings | Oven Thermostat | The oven heats up but drifts 50°F or more from the set point during cooking. |

The Audible Click Test

Mechanical thermostats provide physical feedback. You can perform this test without any tools. Start with the oven in the Off position. Slowly rotate the temperature knob to a low setting, such as 200°F.

Listen closely. A functioning mechanical thermostat should produce a distinct click sound as the internal contacts close to complete the circuit. If the knob rotates smoothly without any mechanical sound or resistance, the internal contacts are likely fused or broken. This silence confirms the need for a replacement.

Multimeter Validation (Optional but Recommended)

For a scientific confirmation, use a multimeter. This requires unplugging the appliance and accessing the thermostat terminals. Set your multimeter to the continuity setting (often symbolized by a sound wave icon). Place the probes on the thermostat terminals.

When the knob is Off, there should be no continuity (infinite resistance). When you turn the knob On, the meter should beep or show zero resistance. If the meter shows no continuity while the knob is turned on, the electrical path is broken inside the component.

Preparation and Risk Assessment (TCO & Safety)

Successful DIY projects depend on preparation. You must evaluate the costs and manage the risks associated with high-voltage appliances. This phase ensures you have the right parts and a safe environment.

Total Cost of Ownership (TCO) Analysis

Repair vs. Replace: Consider the age of your appliance. If your oven is over 15 years old and the replacement part exceeds $150, you might be reaching the point of diminishing returns. In such cases, putting that money toward a new, energy-efficient unit usually offers a better Return on Investment (ROI).

Sourcing the Right Part: Precision matters. Do not rely solely on the brand name. Manufacturers change suppliers frequently. Open the oven door or pull out the bottom drawer to find the data plate containing the specific Model Number. Search using this alphanumeric code. Avoid Universal thermostats unless you are experienced with calibration; they often require complex adjustments that frustrate average users.

Safety & Compliance

Working on an electric oven involves 240-volt circuits, which are lethal if mishandled. Follow these strict safety protocols:

Power Isolation: Do not just turn the knob off. You must perform a lockout/tagout procedure. For electric ovens, go to your home’s breaker panel and flip the dedicated breaker to Off. Unplugging the unit is also effective, but hardwired wall ovens require breaker isolation.

Capacitor Discharge: Modern ovens with digital displays often use capacitors on the control board. These components can store electrical charge even after power is cut. Wait at least five minutes after cutting power before touching internal components to allow this charge to dissipate.

Required Toolkit

Gather these tools before you start. Searching for a screwdriver mid-repair increases the chance of errors.

Screwdrivers: A standard Phillips head is essential. Check your specific model for Torx or Hex security screws.

Needle-nose Pliers: Essential for removing stubborn spade connectors from the old thermostat without damaging the wires.

The Experience Tool: A 3-foot length of strong string or twine. This is critical for the capillary tube routing trick.

Work Gloves: The internal edges of oven sheet metal are often razor-sharp. Protect your hands.

Access Strategy: Built-In Ovens vs. Freestanding Ranges

Accessing the thermostat housing requires different strategies depending on your appliance type. Identify your scenario below.

Scenario A: Freestanding Electric Range

This is the most common configuration. The oven and cooktop are a single unit. You will need to pull the unit away from the wall to reach the back.

Locate the rear maintenance panel. It is typically secured by 4 to 6 hex-head screws. Remove these to expose the wiring and the back of the control panel. Note that for some high-end specialty ranges, such as ILVE models, access is more complex. You may need to disassemble the top burners and drip trays to access the control housing from the front.

Scenario B: Built-in Wall Ovens

Wall ovens present a unique challenge: gravity. You usually cannot access the wiring without sliding the unit out of the cabinet.

The Tipping Hazard: Before removing any trim screws, place a sturdy table or crate directly in front of the oven. Adjust the height to match the bottom of the oven. When you slide the heavy unit forward, it needs immediate support. Do not attempt to hold the oven weight yourself while working.

Slide the unit forward just enough—usually 4 to 6 inches—to expose the screws securing the top control panel housing. This minimizes the risk of the oven falling completely out of the cabinet.

Step-by-Step Electric Oven Thermostat Replacement

Once you have access, follow this sequence to replace the component. Patience here prevents broken wires and damaged insulation.

Step 1: The Documentation Snapshot

Tech sheets and wiring diagrams can be confusing. Before you touch a single wire, take your smartphone and snap a high-resolution photo of the current wiring configuration. Capture clearly which color wire goes to which terminal on the old thermostat. This photo serves as your fail-safe reference during reassembly.

Step 2: Disconnecting the Control Unit

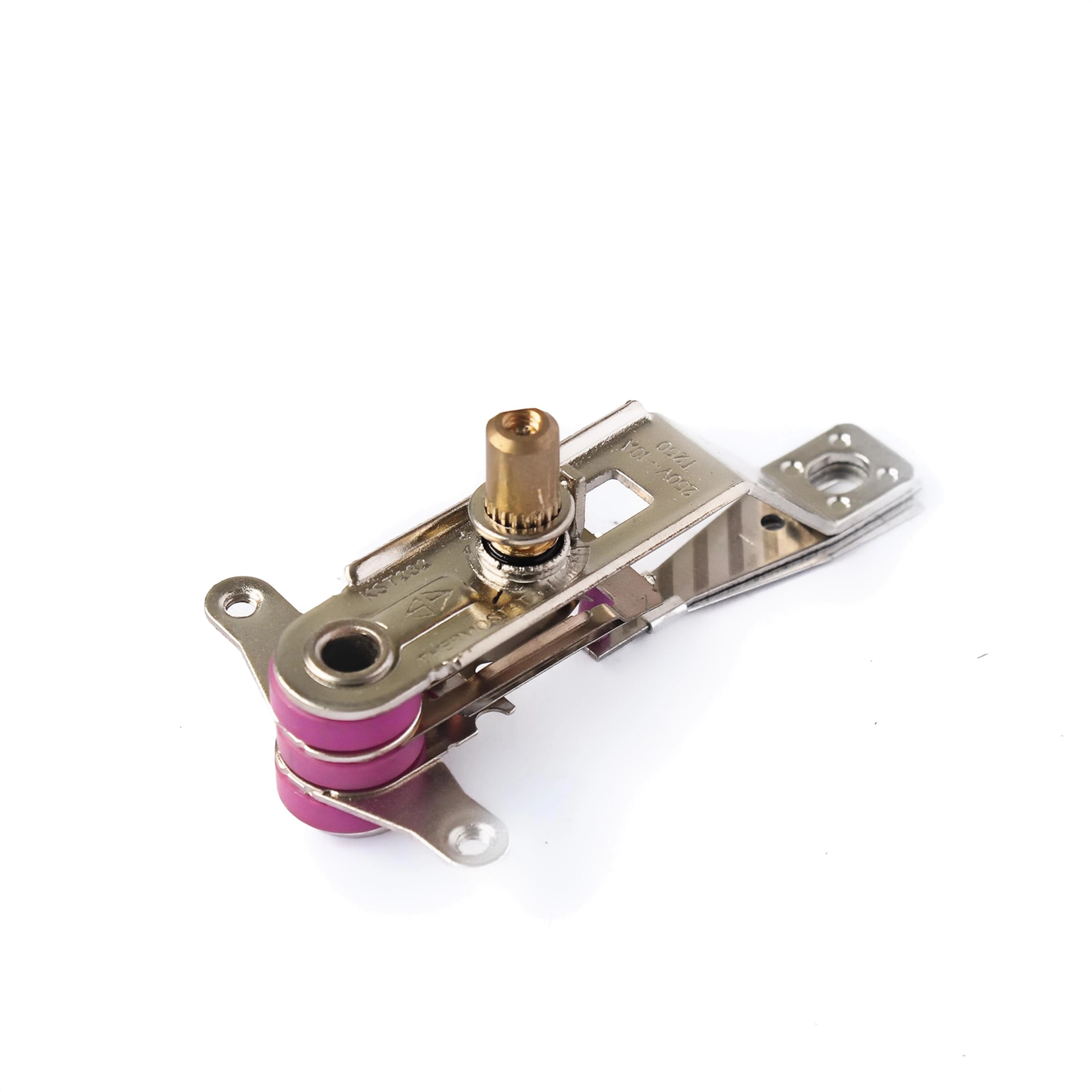

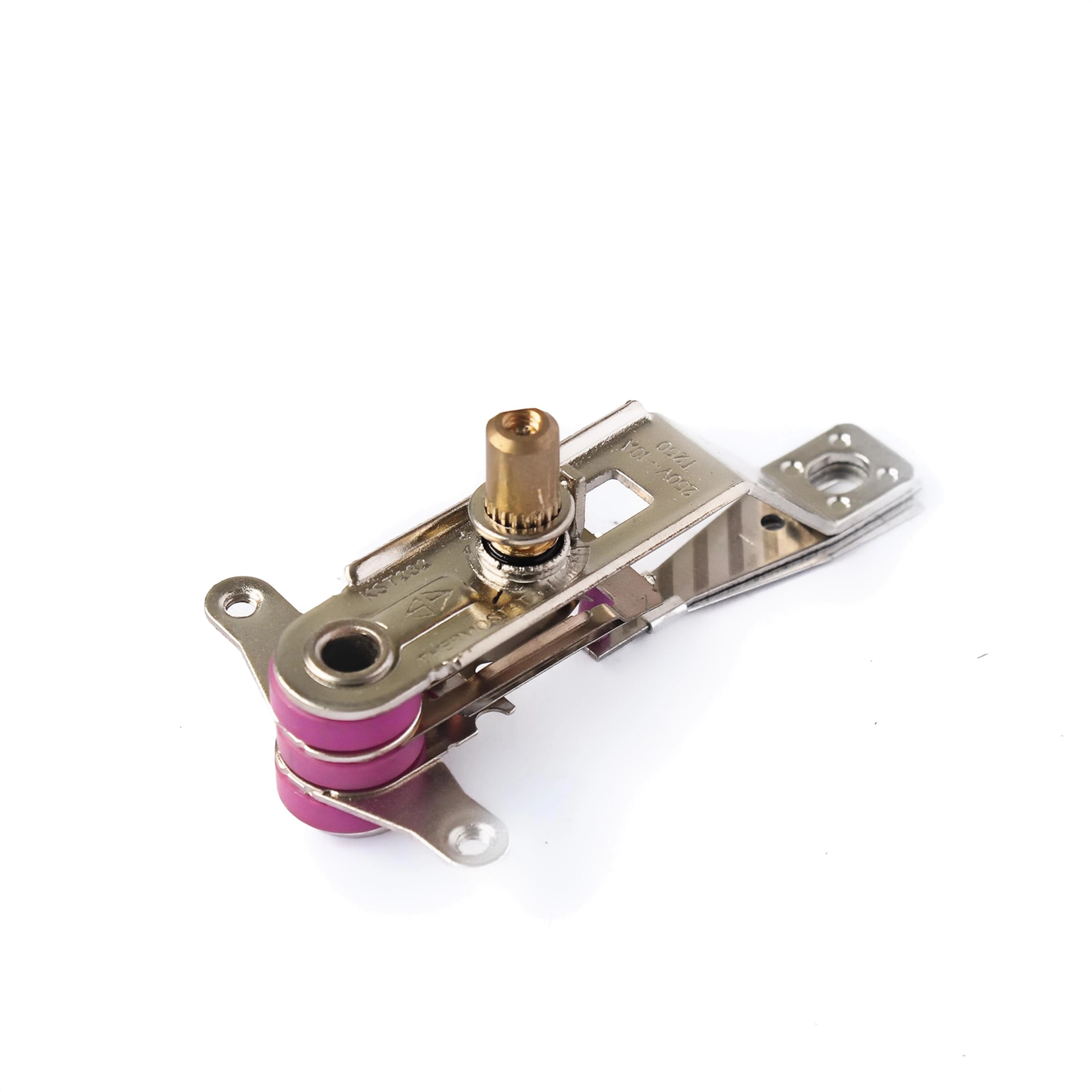

Move to the front of the oven. Pull the temperature knob straight off the shaft. Behind it, you will typically find two retaining screws holding the thermostat to the control panel. Unscrew them.

Go back to the rear of the panel. The thermostat should now be loose. Using your needle-nose pliers, disconnect the wires. If you did not take a photo, transfer the wires one by one from the old unit to the new Electric Oven Thermostat. If you are waiting to install the new part, label each wire with masking tape.

Step 3: Managing the Capillary Tube (The Sensing Bulb)

The mechanical thermostat has a long copper tube attached to it. This tube ends in a sensing bulb located inside the oven cavity. This step is where most DIY mistakes happen. The tube is filled with gas and is fragile; kinking it destroys the part.

Open the oven door and locate the sensing bulb, usually clipped to the top or back wall. Carefully unclip it. Now, you must route this bulb out through the back of the oven without losing the path through the insulation.

The String Trick (High-Value Expert Tip)

Tie It: Before pulling the old tube out from the back, tie your 3-foot string securely to the sensing bulb inside the oven cavity.

Pull It: Go to the back of the oven and gently pull the old thermostat and tube out. As you pull, the string will follow the tube through the hole and the fiberglass insulation layers.

Swap It: Once the old unit is out, untie the string from the old bulb. Tie the string securely to the sensing bulb of your new thermostat.

Reverse It: Go back to the oven cavity. Pull the string gently to guide the new sensing bulb back through the insulation and into the oven.

Using this method prevents the new tube from getting snagged in the fiberglass or kinking against internal metal structures. It ensures the tube follows the exact factory path.

Step 4: Reassembly and Clip Security

With the new bulb inside the cavity, snap it back into the retaining clips. Warning: The sensing bulb must not touch the heating element or the metal walls of the oven. Direct contact causes false readings and grounding risks. It must be suspended in the air by the clips.

Return to the rear panel. Secure the thermostat body to the control panel with the mounting screws. Reattach the knob. Reinstall the rear maintenance panel and push the oven back into position.

Post-Installation: Testing and Calibration

Do not cook a meal immediately. You must verify that the repair was successful and safe.

The Smoke Test

Turn the breaker back on. Set the oven to 350°F (175°C). Monitor the Preheat or cycling light. It should turn on immediately. Stay in the kitchen and watch. After approximately 10 to 15 minutes, the light should turn off. This indicates the thermostat believes it has reached the target temperature. If the light never turns off or the oven gets dangerously hot, shut the power off immediately.

Temperature Accuracy Check

Thermostats are mass-produced and may drift slightly. Place an independent analog oven thermometer in the center of the middle rack. Allow the oven to cycle on and off at least three times. This stabilizes the internal heat.

Check the thermometer reading. Calculate the average. If the oven is set to 350°F but averages 325°F or 375°F, you may need to calibrate. Pull the knob off again. Look inside the hollow shaft of the knob stem. Many mechanical thermostats have a tiny set screw inside. Turning this screw slightly can adjust the temperature calibration. Refer to your specific manual for directional adjustments (clockwise usually lowers temp; counter-clockwise raises it).

Maintenance: Prolonging the New Thermostat's Life

Now that your oven is fixed, simple habits can prevent future failures.

The Self-Clean Hazard

The self-cleaning feature is convenient but destructive. It raises the internal temperature to over 800°F to incinerate food residue. This extreme heat is the number one killer of replacement thermostats and thermal fuses. To extend the life of your new component, avoid the self-cleaning cycle. Use manual cleaners or steam methods instead.

Physical Handling

Avoid hanging heavy wet towels on the oven door handle. The weight warps the door seal over time. A poor seal lets heat escape, forcing the thermostat to cycle the heating element constantly to compensate. This overwork shortens the component's lifespan. Additionally, be gentle with the control knob. Never force it past the Broil stop point, as this can snap the internal mechanical stops.

Conclusion

Replacing an oven thermostat is a precise task, but it is a manageable DIY project for most homeowners. It restores the joy of predictable cooking and extends the life of a major appliance. By following the diagnostic steps, ensuring safety with power isolation, and utilizing the String Trick for installation, you avoid common pitfalls and expensive labor bills.

Remember to always source OEM parts to ensure voltage compatibility and proper fitment. If you are ready to tackle this repair, ensure the power is off, grab your string, and get your kitchen back in working order.

FAQ

Q: How do I know if it's the thermostat or the heating element?

A: Perform a visual check and a symptom check. If the heating element has visible blisters or never glows, the element is likely broken. If the element works but the temperature fluctuates wildly, burns food, or the preheat light never turns off, the thermostat is the likely culprit. The Audible Click test on the knob can also confirm mechanical thermostat failure.

Q: Can I use a universal oven thermostat?

A: It is generally not recommended. Universal thermostats often require complex calibration and physical modifications to the mounting brackets or shaft length. Using a model-specific part ensures the voltage ratings match and the capillary tube length is correct for your oven cavity, ensuring safer and easier installation.

Q: Why does my oven temperature drop after replacing the thermostat?

A: New thermostats may not be perfectly calibrated from the factory. If the temperature is consistently lower or higher than the setting, check the hollow shaft behind the control knob. There is often a small set screw that allows you to fine-tune the temperature calibration without replacing the part again.

Q: Is it safe to use the oven if the sensing bulb clip is broken?

A: No. The sensing bulb must be suspended in the air, away from the oven walls and heating elements. If it touches the metal wall, it will read the metal temperature rather than the air temperature, leading to inaccurate cooking. If it touches the heating element, it can damage the bulb or cause electrical issues.